Get Your Free Quote…!

A Paddle Flocculator is a key piece of equipment used in water and wastewater treatment processes to promote flocculation – the gentle mixing of coagulated particles to form larger aggregates (flocs) that can be easily separated through sedimentation or filtration. Designed for optimal energy efficiency, uniform mixing, and controlled shear, paddle flocculators are widely used in municipal, industrial, and process water treatment applications.

At Verito, we offer robust, efficient, and customizable paddle flocculators engineered for reliable operation under varying process conditions. Our designs focus on performance, durability, ease of maintenance, and energy optimization.

Working Principle

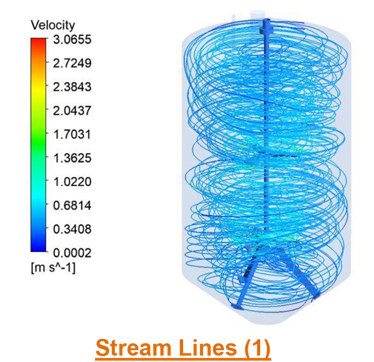

The paddle flocculator operates by imparting controlled, low-intensity mixing energy to facilitate the collision and agglomeration of particles in the water. Coagulants added upstream cause destabilization of fine particles, and the paddle flocculator ensures uniform distribution and sufficient contact time for particles to form flocs.

Key principles involved include:

Paddle Design

Shaft & Support

Drive Mechanism

Tank Integration

Material Selection

| Parameter | Typical Range / Details |

|---|---|

| Paddle Width | Custom up to 5000 mm |

| Shaft Material | SS304 / SS316 / Carbon Steel (epoxy coated) |

| Paddle Material | SS304 / SS316 / FRP |

| Bearing Type | Heavy-duty sealed bearings |

| Drive Type | Electric motor with VFD control |

| Mounting | Top-entry, side-entry or center shaft |

| Application Area | Municipal water, wastewater, industrial effluent treatment, chemical processing, desalination |

Applications

Advantages of Paddle Flocculator

Why Choose Verito Paddle Flocculators?

Contact Us

For detailed consultation, customized design support, or to request technical data sheets and pricing, reach out to our experts at Verito. We help you build smarter, more efficient, and sustainable water and wastewater treatment systems with reliable paddle flocculators tailored to your needs.