Understanding the FGD Challenge

Flue Gas Desulfurization (FGD) is a critical process in reducing sulfur dioxide (SO₂) emissions from

industrial exhaust gases, particularly in power plants and large-scale industrial operations. The

agitator is a vital component in this process, ensuring the effective mixing of slurries to maximize

the contact between the flue gas and the absorbent, leading to efficient SO₂ removal.

Verito: Your FGD Agitation Partner

Verito is a global leader in designing and manufacturing cutting-edge agitator solutions specifically

tailored for FGD applications.

Our FGD agitators are specifically designed to handle the unique challenges presented by different

types of desulfurization systems, including limestone, gypsum, magnesium oxide, and ammonia-based

FGD processes. A key feature of our agitators is the use of Alloy 926 or higher-grade materials in

impeller construction, ensuring exceptional resistance to corrosion and wear in aggressive

environments. Here’s a detailed look at how Verito agitators enhance each critical aspect of the FGD

system:

Absorber Agitators

Application

- In the absorber, where flue gas comes into contact with the slurry, effective mixing is

crucial to maximize the contact area between the gas and the absorbent.

Technical Features

- Verito’s side entry agitators are designed to provide thorough mixing within the absorber,

ensuring that the absorbent (e.g., limestone slurry) interacts effectively with the flue gas

to optimize sulfur dioxide (SO₂) removal. These agitators are built to withstand the highly

corrosive environment of the absorber.

Limestone Slurry Preparation and Storage

Application

- Limestone slurry is a key absorbent in many FGD processes, requiring precise preparation and

consistent mixing to maintain slurry homogeneity.

Technical Features

- Our top entry agitators are employed in limestone slurry tanks to ensure that the slurry

remains uniform, preventing sedimentation and ensuring a consistent feed to the absorber.

These agitators are designed for high efficiency and low maintenance, making them ideal for

continuous operation.

Absorber Drain Tank

Application

- The absorber drain tank collects slurry that is not fully processed and requires further

treatment or recirculation.

Technical Features

- Verito agitators in the absorber drain tank maintain slurry movement, preventing settling

and ensuring that the slurry can be easily pumped for further processing or disposal.

Reclaim Water/Reuse Water Tanks

Application

- Reclaim and reuse water tanks are essential for the recycling of process water within the

FGD system, reducing overall water consumption and waste.

Technical Features

- Our top entry agitators are tailored for water tanks, providing efficient mixing that

ensures consistent water quality and prevents stagnation. These agitators are optimized for

energy efficiency and longevity, even in large tanks.

Gypsum Slurry

Application

- Gypsum, a byproduct of the FGD process, is typically collected as a slurry and requires

careful handling to avoid blockages and ensure smooth transport and processing.

Technical Features

- Verito agitators are specifically designed for gypsum slurry tanks, offering robust mixing

that prevents the slurry from solidifying or settling. This ensures that the gypsum can be

efficiently processed or transported for further use.

Area Sumps and Wastewater Treatment

Application

- Sumps collect various liquids from the FGD process, including washdown water and other waste

streams, which must be mixed and treated before disposal.

Technical Features

- Our agitators for area sumps and wastewater treatment tanks are designed to handle high

solids content and aggressive chemicals, ensuring that the contents remain homogenized for

efficient pumping and treatment.

Chloride Bleed Wastewater Treatment / Heavy Metals Removal

Application

- Chloride bleed and heavy metals removal are critical to maintaining the efficiency of the

FGD system and meeting environmental discharge standards.

Technical Features

- Verito agitators in these systems ensure thorough mixing of reagents and wastewater,

enhancing the effectiveness of chemical treatments designed to precipitate and remove

contaminants.

Fly Ash Make-Down and Storage

Application

- Fly ash, another byproduct of the combustion process, must be properly handled and stored to

prevent dust and ensure easy transport.

Technical Features

- Verito agitators in fly ash make-down tanks provide efficient mixing that prevents the ash

from clumping, ensuring a uniform slurry that can be easily pumped and processed.

Technical Specification & Capabilities

| Motor Power |

Upto 100 kW |

| % Solid Concentration |

0-70% (W/W) |

| Impeller Diameter |

300mm – 4000mm |

| Shaft Diameter |

30-300 mm |

| Impeller Type |

Hydrofoil, Wide Foil, Turbine |

| Materials (Wetted Parts) |

EN8+RL, EN24+RL, Alloy 926 or Better Grade |

Customization and Engineering Excellence

Verito’s commitment to customer satisfaction is reflected in our ability to provide tailored

solutions. Our engineering team employs advanced design tools and simulation software to optimize

agitator performance for specific FGD applications.

Material Selection

- We carefully select materials resistant to corrosion and abrasion to ensure long equipment

life

Installation and Commissioning

- Our experts provide comprehensive support to ensure seamless integration of agitator

systems.

Seals and Bearings

- High-performance seals and bearings are used to withstand harsh FGD conditions.

Benefits of Verito Agitation Solutions

- Improved FGD system efficiency and reliability

- Reduced operating costs through energy savings and lower maintenance

- Enhanced environmental performance by maximizing sulfur dioxide removal

- Extended equipment life through robust design and material selection

- Expert support and service throughout the project lifecycle

For more information on how Verito’s FGD agitators can enhance your operations, contact our team

today. We are dedicated to providing solutions that are as unique as your process needs.

What is CFD ?

- Computational Fluid Dynamics (CFD) represents an approved approach within the realm of

fluid mechanics. Its widespread application is evident in industries such as automotive,

aircraft, process, and mixing.

- The primary objective of CFD is to address fluid flow-related inquiries by leveraging

numerical techniques. The governing equations typically revolve around principles like

Navier-Stokes, Euler, or potential-based equations.

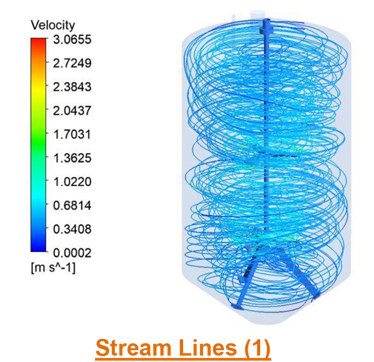

Flow Simulation at Verito

- Verito leverages cutting-edge Computational Fluid Dynamics (CFD) technology, alongside

laboratory experiments and field trials, to design, scale-up, enhance, or modernize

agitators and mixing systems.

- Verito’s engineers utilize CFD technology to gain an in-depth understanding of

velocity distribution, flow patterns, areas with low velocity (referred to as dead

zones, as illustrated in Figures 1, 2 & 3), as well as regions with both low and high

shear rates within various mixing system configurations.

- This enables the testing of multiple system setups and tank agitator designs to

achieve optimal performance. Additionally, CFD technology aids Verito in fine-tuning

impeller blade designs to strike a balance between power requirements and pumping

capacity.

Key Outcomes of CFD-Studies

- In-depth Information of Flow pattern

- Areas with the potential of low mixing intensity can be pinpointed and rectified.

- Availability of crucial process parameters like shear and energy dissipation

- Evaluation of different design options

- Shortened project timelines for complex process mixing systems

- Mitigation of project risks