Get Your Free Quote…!

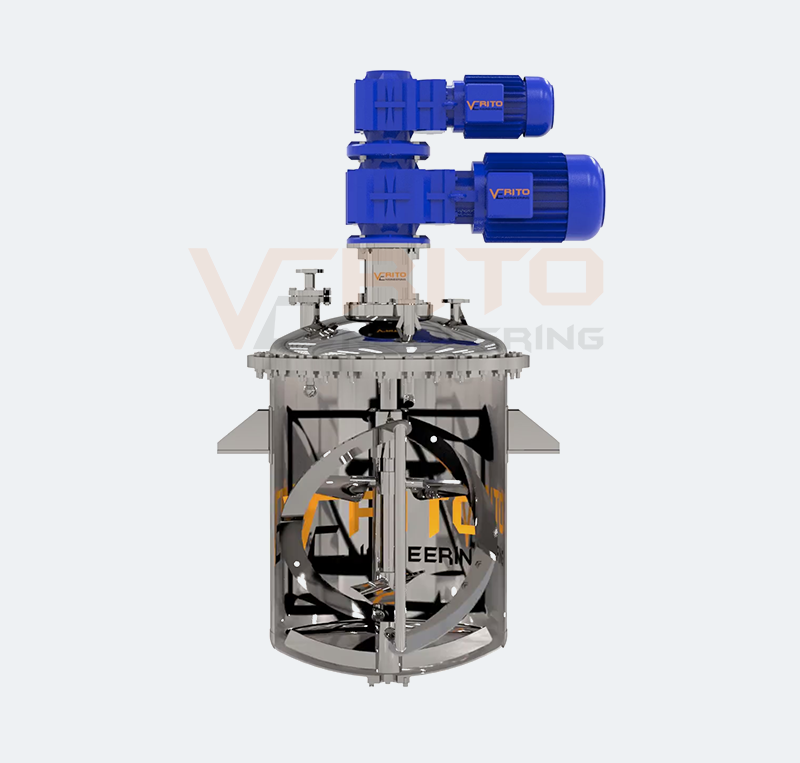

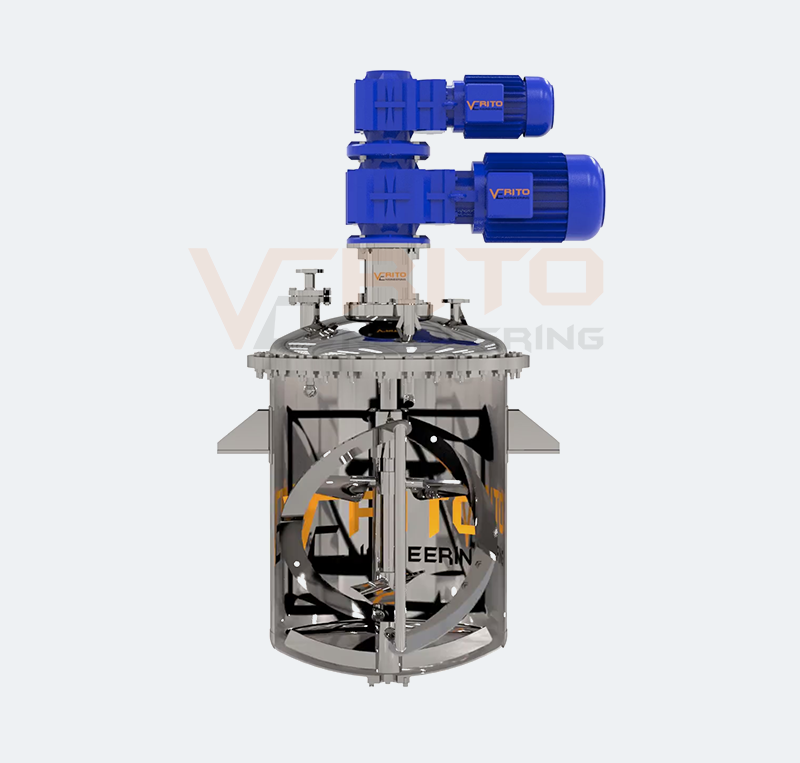

At Verito Engineering Private Limited, we redefine mixing technology with our state-of-the-art Coaxial Agitators. Engineered for the most demanding applications, our coaxial design integrates two independently driven agitators on a single axis, delivering unparalleled control and versatility. This innovative dual-action system is the definitive solution for complex processes involving high-viscosity fluids, delicate suspensions, and challenging homogenization tasks where a single agitator falls short.

Our Coaxial Agitators provide a unique synergy of low-speed, high-torque bulk movement and high-speed, high-shear dispersion, ensuring perfect product consistency every time.

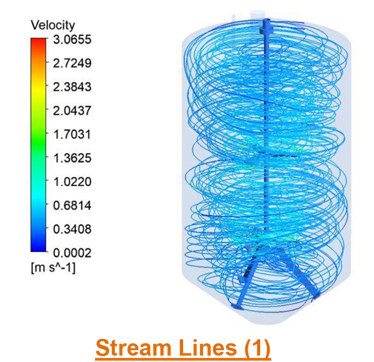

How It Works: The Synergy of Dual-Action Mixing

The genius of the Verito Coaxial Agitator lies in its concentric dual-shaft design

This combination allows for the simultaneous execution of macro-mixing (bulk blending) and micro-mixing (dispersion/emulsification), a feat impossible for conventional single-shaft systems. The result is dramatically reduced batch times, superior product quality, and enhanced operational efficiency.

Verito Coaxial Agitators are not off-the-shelf products; they are custom-engineered solutions. Below are typical specification ranges we work with.

| Parameter | Specification Range |

|---|---|

| Vessel Capacity | 50 Liters to 25,000 Liters |

| Viscosity Handling | Up to 500,000 cP (Centipoise) |

| Motor Power | Outer Anchor: 0.5 HP to 50 HP Inner Disperser: 1 HP to 100 HP |

| Operating Speed (RPM) | Outer Anchor: 10 - 60 RPM (VFD Controlled) Inner Disperser: 300 - 3000 RPM (VFD Controlled) |

| Materials of Contact | SS 304, SS 316, SS 316L, Hastelloy, Duplex Steel |

| Surface Finish | Matte, Mirror Polish (up to 0.4 Ra), Electropolishing |

| Sealing System | Gland Packing, Lip Seal, Single Mechanical Seal, Double Mechanical Seal (Cartridge Type) |

| Mounting | Flange Mounting (Top Entry) as per ASME/DIN standards |

| Optional Features | Wall Scrapers (PTFE/Teflon), Temperature/pH Probes, CIP/SIP Systems, Explosion-proof (Ex) Motors & Controls (ATEX certified), Hydraulic Lift Systems |

Applications Across Industries

The versatility of our Coaxial Agitators makes them indispensable in numerous sectors:

Choosing a Verito Coaxial Agitator is an investment in efficiency, reliability, and quality.