Get Your Free Quote…!

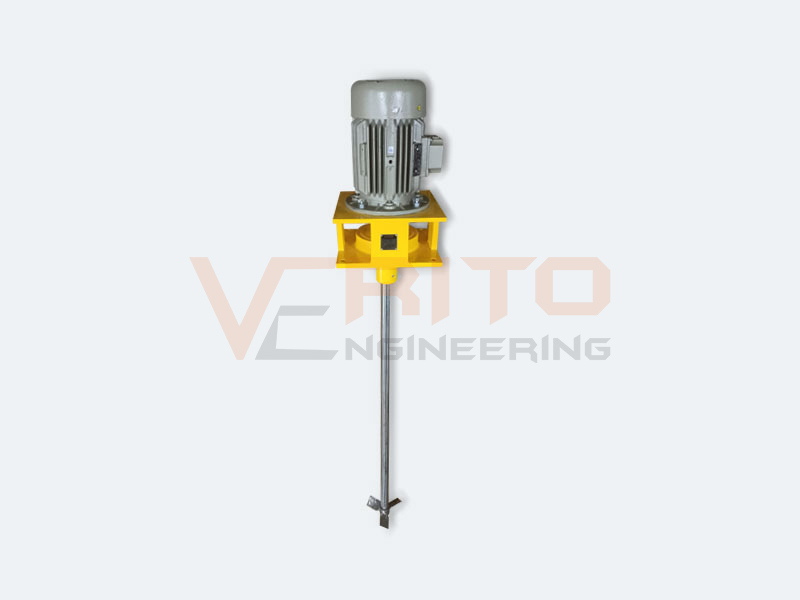

Verito’s direct driven Agitator type is an innovatively designed top flange agitator for use in the food and pharmaceutical industries. It is a mixer without gearbox, so there is no oil/lubricants leakage which could contaminate your product

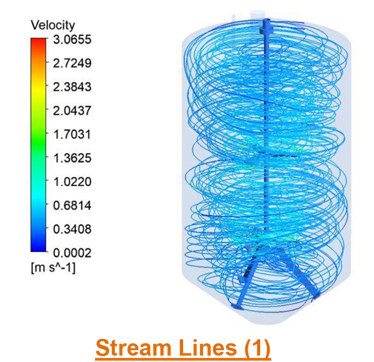

The mixer shaft is directly fitted directly into the drive, eliminating the need for an extra shaft coupling. The High- Speed Agitator are a strong and practically maintenance-free mixer which makes it a perfect solution for applications in the food and pharmaceutical industry. It is suitable for frequency converter-controlled operation.

| Motor Power | 0.1-15 kW |

| Shaft Diameter | 30-300 mm |

| Operating Pressure | Vacuum – 200 bar |

| Impeller Type | High Efficiency Impeller, Propeller, Hydrofoil, Alpha impeller, Turbine, Cowles Disk |

| Materials (Wetted Parts) | MS, EN8, SS316, SS316L, CS, Duplex & Super Duplex Steel |