Get Your Free Quote…!

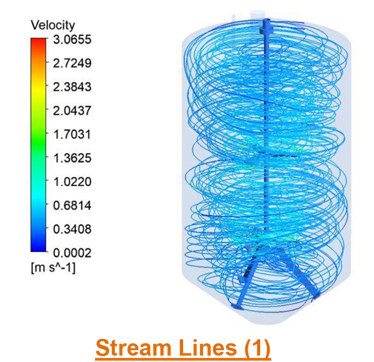

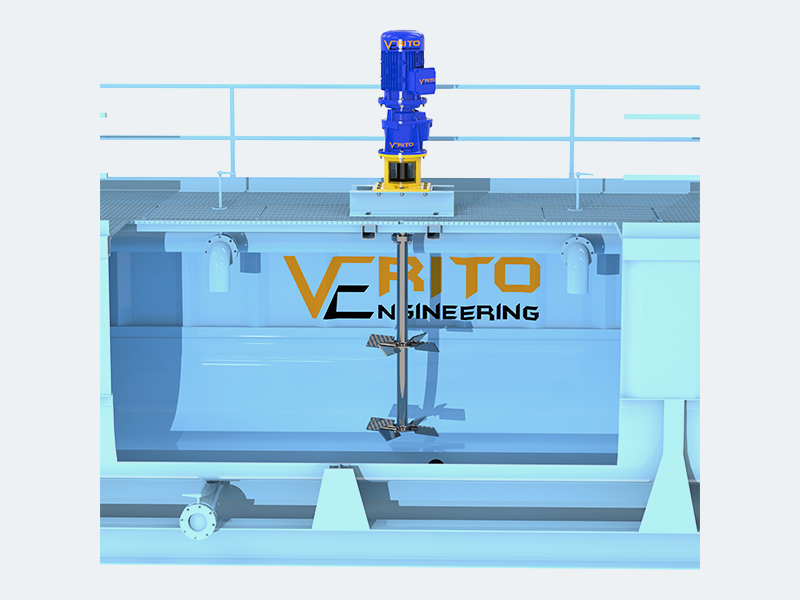

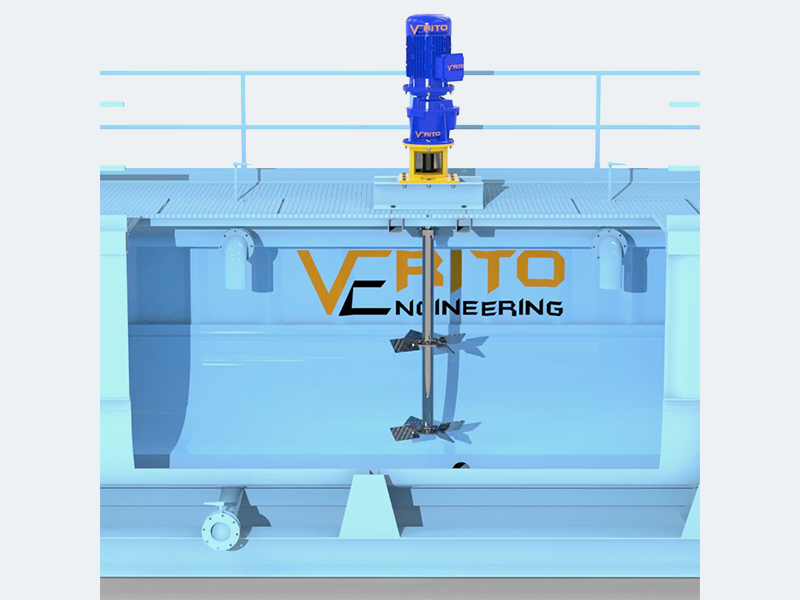

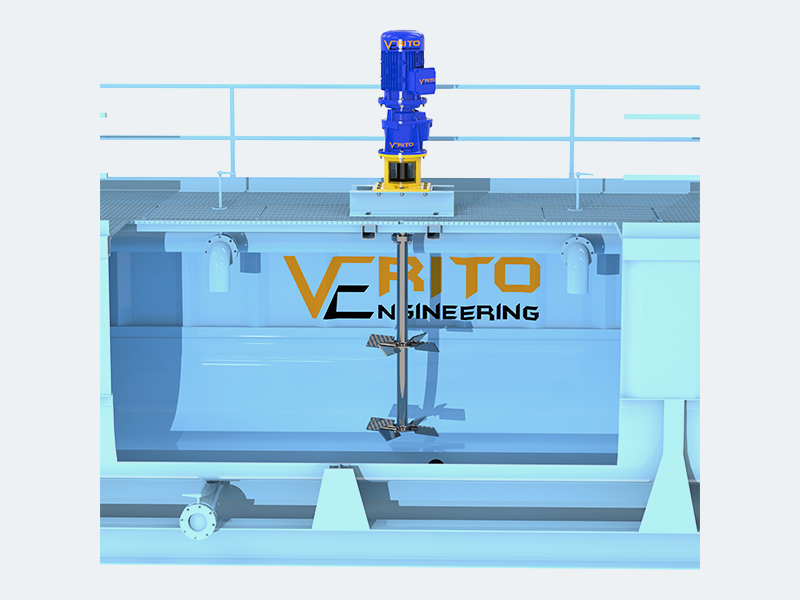

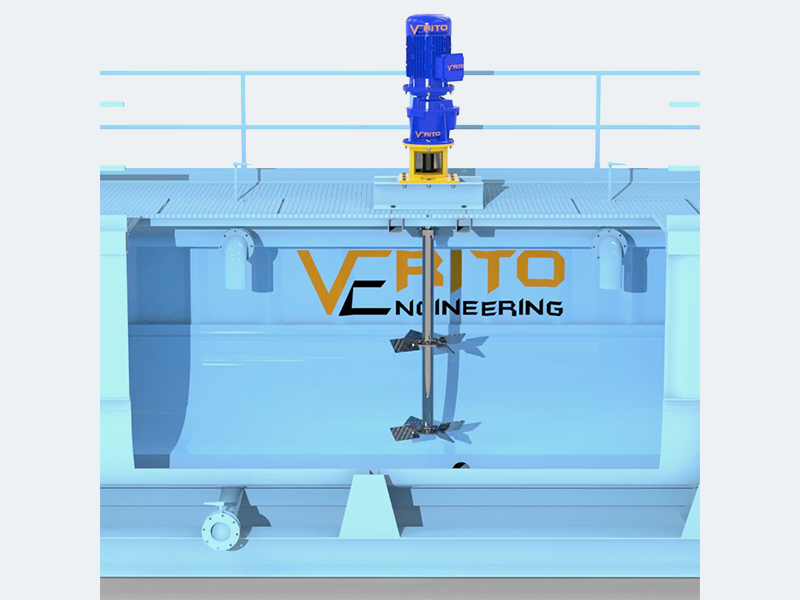

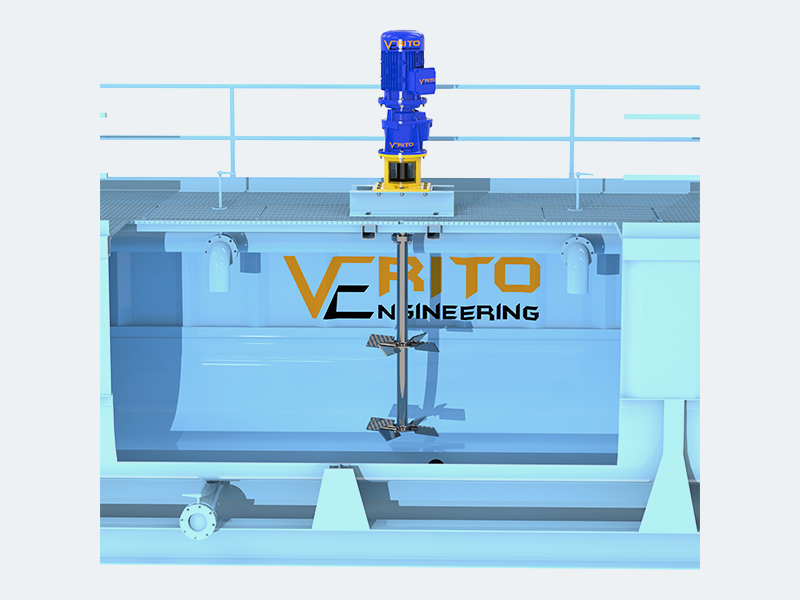

At Verito Engineering Private Limited, we design and manufacture Mud Agitators specifically tailored for the oil & gas, mining, and drilling industries. Our agitators play a crucial role in maintaining the homogeneity of drilling fluids, preventing the settlement of solids, and ensuring efficient mud circulation in mud tanks. Built to handle the demanding requirements of these industries, our agitators are engineered to deliver high-performance mixing even in the harshest environments.

Mud agitators are essential for the proper management of drilling fluids (drilling mud). These fluids are critical to the drilling process, providing cooling, lubrication, and stabilizing pressure. Verito Engineering’s Mud Agitators ensure the effective suspension of solid particles in the drilling fluid, thereby enhancing operational efficiency and extending equipment life.

Key Features:

| Motor Power | 3 HP to 25 HP |

| Motor Type | Explosion-proof, continuous-duty, IE3 efficiency |

| Gearbox Type | Helical bevel or worm gearbox |

| Impeller Types | Canted blade, flat blade, or customized |

| Material of Construction | Carbon steel, Stainless steel (SS304/SS316) |

| Shaft Length | Customizable (up to 5 meters) |

| Speed | 20 to 100 RPM |

| Tank Capacity | Suitable for tanks from 1000 to 50,000 gallons |

| Viscosity Range | Handles low to high viscosity drilling mud |

At Verito Engineering Private Limited, we combine advanced technology, robust engineering, and years of industry experience to deliver mud agitators that meet the highest standards of performance, reliability, and durability. Whether you are operating in oil & gas, mining, or any other heavy-duty industry, our Mud Agitators ensure superior mixing performance, contributing to more efficient, cost-effective, and reliable drilling operations.