Turndown ratio is a key metric in dosing pump selection that directly impacts process control and operational efficiency. This article explains what turndown ratio means, how it influences dosing performance, and how to choose the right pump configuration based on dosing variability requirements.

Define What Turndown Ratio Means in Dosing Systems

Turndown ratio refers to the range between the maximum and minimum flow rate a dosing pump can deliver accurately. A 10:1 turndown ratio means the pump can maintain precise dosing even when operating at 10% of its maximum rated flow. This metric defines how much flexibility the pump offers for varying process loads or batch sizes.

Understand Why Turndown Ratio Affects Dosing Accuracy and Control

Turndown ratio determines how well a pump maintains consistent metering under different flow demands. A low turndown ratio limits the operating range, leading to dosing errors during low-load conditions. High turndown ratios allow the same pump to handle wide-ranging flow requirements without compromising accuracy or requiring frequent adjustments.

Compare Turndown Capabilities of Different Dosing Technologies

Different pump types offer different turndown capabilities based on their control mechanisms and construction. For example:

- Solenoid-driven diaphragm pumps: Typically offer a turndown ratio between 10:1 and 100:1, depending on pulse control and stroke length.

- Motor-driven mechanical diaphragm pumps: Deliver a range between 10:1 to 50:1 with smooth flow but limited fine-tuning at low speeds.

- Stepper motor or servo-controlled pumps: Offer turndown ratios up to 1000:1 with highly accurate flow modulation and full automation compatibility.

Select the Right Turndown Ratio Based on Process Requirements

The ideal turndown ratio depends on how much flow variability the process requires over time. For fixed-batch operations with narrow range variation, a 10:1 ratio often suffices. For continuous processes handling multiple chemicals or changing concentrations, pumps with 100:1 or higher turndown ratios enable greater flexibility without sacrificing control. Always match the pump’s accuracy rating with your lowest dosing requirement.

Analyze the Impact of Turndown Ratio on Maintenance and Pump Life

Operating a pump too close to its minimum or maximum rated limit can reduce lifespan and increase wear. A higher turndown ratio allows more mid-range operation, where mechanical stress and pulsation are lower. Pumps with inadequate turndown require frequent calibration or overdesign, leading to higher maintenance costs. Selecting the right range helps maintain consistent performance across varying loads.

Ensure Compatibility with Control Systems and Automation

Dosing pumps with advanced turndown capabilities integrate better with PLCs and process automation systems. Electronic control via 4–20 mA signals, digital pulses, or Modbus/Profibus interfaces requires pumps to modulate flow smoothly across a broad range. High turndown pumps support dosing feedback loops, allowing real-time adjustment to meet changing chemical demands without manual intervention.

Match Turndown Performance to Industry Applications

Different industries use turndown ratios to meet specific dosing challenges. In water treatment, chlorine and coagulant dosing needs change seasonally, requiring turndown of at least 100:1. In pharmaceutical production, highly accurate micro-dosing at varying concentrations is critical. In chemical blending, one pump often handles multiple fluid types, needing flexibility and repeatability at varying flow rates. Turndown capability enables precision without hardware changes.

Conclusion

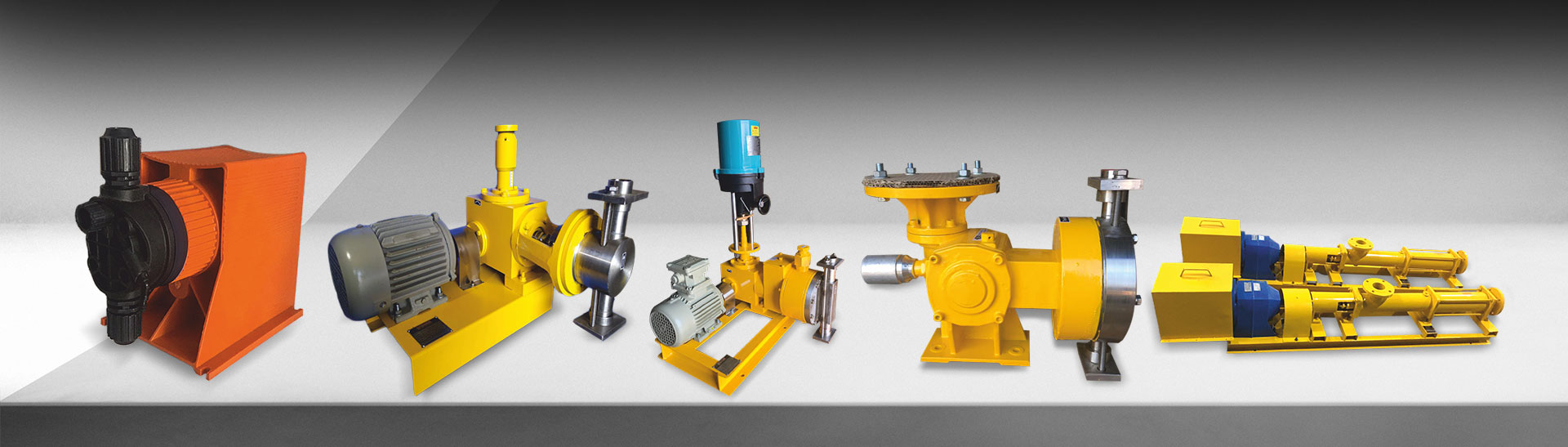

Turndown ratio is a critical factor in selecting dosing pumps that offer flexibility, control, and operational consistency. Choosing the correct ratio ensures accuracy across variable flow conditions, reduces mechanical stress, and supports automation integration. Verito Engineering Pvt. Ltd. offers dosing pumps engineered with wide turndown capabilities to suit demanding industrial and utility applications where precision matters most.