Boilers live or die by their water chemistry. When hardness, oxygen, or pH drift, you get scale, corrosion, foaming, and carryover. This causes wasted fuel, tube failures, and unplanned shutdowns. The challenge is not only using the right chemicals, but delivering them in the right amount at the right time. A well-designed boiler chemical dosing system with a reliable chemical dosing pump keeps parameters in control, protects assets, and maintains steam quality.

Why Boiler Chemical Dosing Is Important

Core Benefits

- Scale prevention: Proper phosphate dosing in boiler feed water ties up hardness and prevents insulating deposits that raise fuel consumption.

- Corrosion control: Hydrazine dosing in boiler feed water scavenges dissolved oxygen in high-pressure circuits. Ammonia dosing in boiler feed water and amine dosing in boiler lines help maintain alkalinity and protect condensate systems.

- Steam purity: Correct conditioning reduces carryover and protects turbines, heat exchangers, and downstream users.

- Compliance and safety: Stable chemistry supports energy audits, safety norms, and reliability KPIs.

If Dosing Is Ignored or Outdated

Expect tube pitting, magnetite layer loss, under-deposit corrosion, frequent blowdowns, wet steam, and escalating maintenance.

Types and Categories: Chemicals and Systems

Core Boiler Dosing Chemicals

- Phosphate programs: Dispersive or coordinated phosphate to control calcium and magnesium hardness.

Typical use: Medium to high pressure boilers requiring hardness management. - Oxygen scavengers: Hydrazine (where allowed), carbohydrazide, DEHA.

Typical use: High pressure systems to remove dissolved oxygen and passivate metal surfaces. - pH and alkalinity builders: Ammonia, caustic soda, tri-sodium phosphate.

Typical use: Maintaining boiler water pH and forming protective magnetite layers. - Neutralizing and filming amines: Morpholine, cyclohexylamine, or filming agents.

Typical use: Condensate return line protection against carbonic acid corrosion. - Antifoams and dispersants: Reduce carryover and keep deposits mobile.

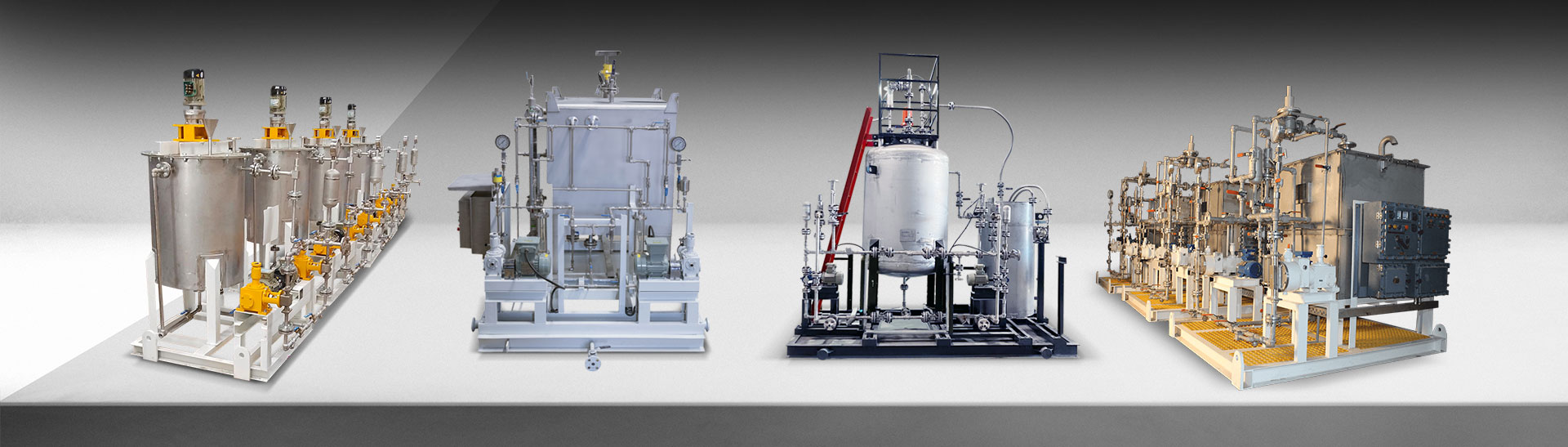

System Configurations

- Simple manual dosing tanks: For small packaged boilers with stable load.

- Semi-automatic skid: Metering pumps with local controllers, level switches, and interlocks.

- Fully automatic dosing system in boiler house: Integrated with feedwater flow, ORP, pH, and phosphate analyzers, plus PLC or DCS connectivity.

Typical Architecture

Feedwater tank or deaerator → inline analyzers (pH, conductivity, phosphate, ORP) → boiler chemical feed pump with calibration column, backpressure valve, and pulsation dampener → injection quills on feedwater line, drum, or condensate header → control signals from PLC or local controller.

Benefits and Advantages

- Performance: Lower fuel bill through clean heat-transfer surfaces and stable steam quality.

- Reliability: Fewer tube leaks, reduced water hammer, and longer asset life.

- Operational ease: Closed-loop control trims chemical consumption and reduces manual intervention.

- Business impact: Reduced downtime, predictable maintenance windows, and better audit outcomes.

- Sustainability: Lower blowdown, less chemical waste, and optimized water use.

Types of Dosing Pumps for Boiler Applications

- Mechanical diaphragm metering pumps: Rugged, good material options, suitable for most conditioning chemicals.

- Hydraulic diaphragm pumps: Oil-backed diaphragm, excellent for high pressure and aggressive media with tight accuracy.

- Plunger metering pumps: High pressure capability and precise stroking for clean, non-abrasive fluids.

- Solenoid metering pumps: Compact, economical, best for low to medium flows and OEM skids.

Stroke Control Considerations

At very low flows, keep stroke length healthy and reduce speed for better valve seating. For wider turndown, combine stroke and speed.

How to Choose the Right Boiler Chemical Dosing System

Key Selection Factors

- Boiler pressure and load profile: High-pressure units with variable load need tighter control and faster response.

- Chemical properties: Viscosity, off-gassing tendency, and compatibility drive material selection for pump heads, valves, and seals.

- Required turndown: Define minimum and maximum feed rates; many programs need 10:1 to 100:1 turndown.

- Control strategy: Manual, on–off, proportional, or full PID using flow-paced dosing tied to feedwater flow.

- Instrumentation: Inline phosphate analyzers, ORP for scavengers, conductivity for TDS control, and pH for condensate.

- Integration: 4–20 mA, pulse, or Modbus to PLC/DCS; interlocks with deaerator levels, boiler trips, and blowdown controls.

- Maintenance: Access to calibration columns, flush points, and isolation valves for safe service.

Small-Scale vs Large-Scale Setups

- Small packaged boilers: Solenoid or small diaphragm pumps, manual setpoint, periodic grab sampling, and flow pacing if available.

- Large utility or process boilers: Hydraulic diaphragm or plunger pumps, duty-standby redundancy, analyzers, and PLC-based flow-paced PID dosing.

Quick Decision Checklist

- Are injection points correctly located and downstream of mixing turbulence?

- Is a backpressure valve installed to stabilize metering?

- Do we have calibration columns and isolation valves for each chemical line?

- Are materials (SS316, PVDF, PTFE, EPDM, FKM) compatible with selected chemicals and temperature?

- Is the system interlocked with boiler trips and low chemical level alarms?

Considerations: Efficiency, Cost, Sustainability

- ROI and lifecycle cost: Clean heat-transfer surfaces save fuel; accurate dosing reduces blowdown and chemical consumption.

- Energy efficiency: Proper dosing lowers stack losses and cuts pump energy through fewer corrective cycles.

- Water stewardship: Optimized cycles of concentration reduce makeup water and wastewater.

- Safety: Provide secondary containment, eyewash, pressure relief, and non-return valves. Document handling of hydrazine and amines, with clear PPE guidance and local compliance.

How Each Program Works in Practice

Phosphate Dosing in Boiler

Why It Matters

Phosphate precipitates residual hardness in a non-adherent form and buffers alkalinity.

Where to Dose

Usually into the drum or feedwater line, depending on program.

Control Tip

Track phosphate residuals and free caustic. Avoid overfeeding that can cause under-deposit caustic corrosion.

Hydrazine Dosing in Boiler Feed Water

Purpose

Hydrazine scavenges oxygen and promotes a passive magnetite layer on steel.

Caution

Check plant policy and regulations. Where restricted, shift to carbohydrazide or DEHA.

Control Tip

Use ORP or fixed ppm per unit feedwater flow. Keep excess within recommended limits.

Ammonia Dosing in Boiler Feed Water

Purpose

Raises condensate pH and neutralizes carbonic acid.

Control Tip

Flow-pacing tied to condensate return rates. Monitor pH at multiple return points.

Morpholine Dosing in Boiler Feed Water

Why Morpholine

It is a volatile neutralizing amine with good distribution.

Control Tip

Balance with other neutralizing amines for full system coverage. Mind FDA or industry-specific restrictions where applicable.

Installation and Commissioning Best Practices

- Injection quills: Position into the flow with corrosion-resistant quills and check valves.

- Hydraulics first: Short, flooded suction lines. Use foot valves with strainers where needed. Eliminate air pockets.

- Stabilize metering: Add backpressure valves and pulsation dampeners to reduce flow ripple.

- Calibrate: Use calibration columns to verify actual flow at several setpoints. Record a stroke-versus-delivery curve if the pump allows.

- Analyzer maintenance: Calibrate pH, ORP, and phosphate analyzers with fresh standards.

- Documentation: Create SOPs for chemical makeup, pump setting, alarm response, and safety.

Frequently Asked Questions

What is the best chemical for boiler dosing?

It depends on pressure, metallurgy, makeup quality, and return condensate. Typical suites include phosphate, an oxygen scavenger, alkalinity adjusters, and neutralizing or filming amines.

Where should I inject chemicals?

Common points are the feedwater line downstream of the deaerator, the boiler drum for phosphate, and the condensate header for amines. Always use proper injection quills and non-return valves.

How does a stroke pump fit here?

A metering pump with stroke and speed control delivers accurate, repeatable chemical feed. Keeping stroke length healthy and trimming flow by speed often gives better low-rate accuracy.

Can I run a single pump for multiple chemicals?

No. Separate pumps and isolated lines prevent cross contamination and allow independent control.

Do I need online analyzers?

For critical boilers, yes. pH, ORP, conductivity, and phosphate analyzers enable closed-loop control and reduce manual testing.

How often should I check residuals?

Daily grab samples at minimum for small systems. High-pressure systems often require shift-wise checks plus analyzer trend review.

Is hydrazine safe to use?

Hydrazine is effective but hazardous. Many sites now prefer alternatives like carbohydrazide or DEHA. Follow site safety rules and local regulations.

Buyer’s Guide and Decision Matrix

Compare Options By

- Pressure rating and required accuracy

- Turndown ratio and control method

- Materials compatibility with each boiler dosing chemical

- Redundancy and changeover (duty-standby)

- Integration with PLC, alarms, and data logging

- Service access, spares, and documentation

Quick Matrix Ideas

- If pressure > 25 bar and chemistry is aggressive, consider hydraulic diaphragm pumps with PTFE diaphragms and SS316 or Hastelloy wet parts.

- If compact, low flow, and budget sensitive, a solenoid metering pump can work with proper backpressure control.

- For wide turndown with tight accuracy, use a diaphragm or plunger metering pump, keep stroke around 60–80%, and modulate speed.

Boiler reliability starts with water chemistry, and water chemistry depends on precise, reliable chemical feed. The right boiler chemical dosing approach aligns chemicals, metering hardware, injection points, and controls. Define your targets, choose compatible materials, and commission with calibration and analyzer verification. If you want help building a flow-paced, analyzer-driven boiler chemical dosing system, we can share a short checklist tailored to your pressure, load, and makeup quality.