When water treatment, food and beverage, chemicals, or pharmaceuticals aim for consistent quality, pH control becomes mission-critical. Tiny deviations in acidity or alkalinity can ruin batches, corrode equipment, reduce microbial safety, or trigger compliance failures. Manual dosing or guesswork often leads to rework, downtime, and unnecessary chemical consumption.

The real challenge is not just hitting the pH target once—it is maintaining it continuously as flow, load, and temperature change. A pH dosing pump working with a pH controller solves this by metering neutralizing chemicals precisely and automatically, keeping processes stable and audit-ready.

Why a pH Dosing Pump Is Important

A pH dosing system is the backbone of repeatable pH control. It is critical for wastewater plants, ETPs, STPs, WTPs, and process lines because it offers:

- Accuracy and repeatability: Meter defined volumes per stroke or per minute for the same response every time.

- Closed-loop stability: A pH controller and dosing pump form a feedback loop. The controller reads pH and adjusts pump output to hold the setpoint.

- Compliance and safety: Consistent pH supports discharge norms, product specs, and downstream equipment life.

- Lower total cost: Reduced chemical wastage and fewer off-spec batches cut operating costs.

What happens if you skip this? Frequent pH swings, over-dosing, corrosion, biological upsets, and regulatory risk.

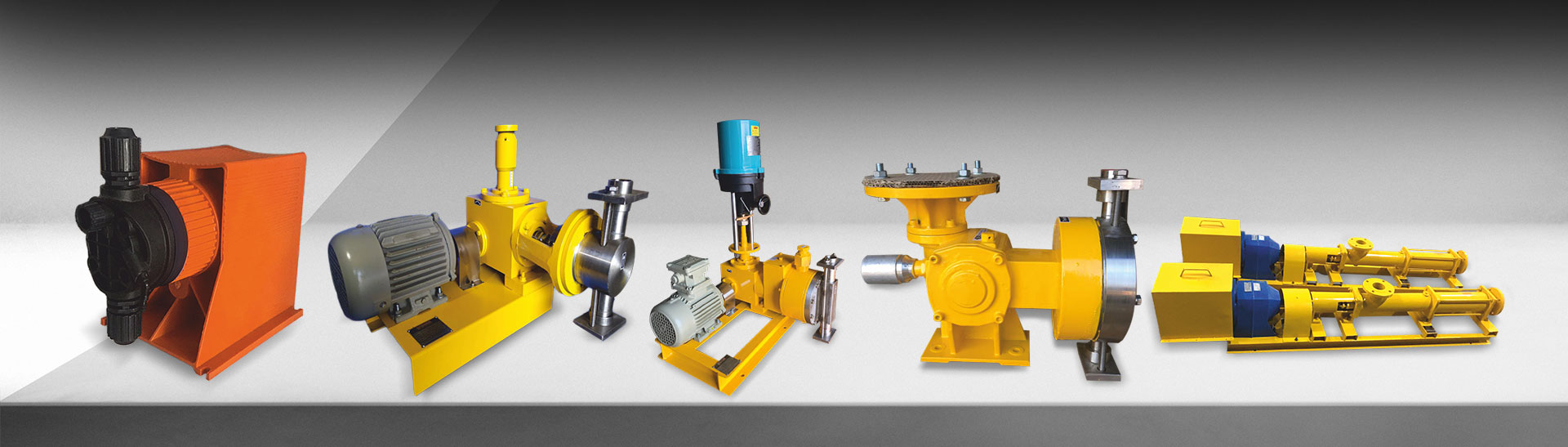

Types of pH Dosing Pumps and Systems

1) Mechanical Diaphragm Metering Pumps

Positive displacement with a flexible diaphragm. Good chemical compatibility and simple maintenance.

Typical use: General water treatment, cooling towers, boiler feed conditioning.

2) Hydraulic Diaphragm Metering Pumps

Oil-backed diaphragm for high pressures and safer operation with aggressive media.

Typical use: Chemical plants, refinery utilities, critical pH neutralization where leak-free design matters.

3) Solenoid (Electromagnetic) Dosing Pumps

Pulse-driven strokes, compact, and cost-effective.

Typical use: Laboratories, low-to-medium flow pH correction, OEM skids.

4) Peristaltic Dosing Pumps

Tubing compression moves fluid. Excellent for shear-sensitive or viscous media and easy maintenance.

Typical use: Hypochlorite, polymer, food-grade additives, small ETPs.

5) Integrated pH Controller + Pump Packages

Pre-engineered automatic pH dosing systems with pH sensor, transmitter, controller, dosing pump, and safety interlocks.

Typical use: Turnkey WTP, ETP, STP panels, compact skids for OEMs and EPC projects.

Typical System Architecture

Signal & Flow Path:

- pH sensor

- Transmitter

- Controller with setpoint and PID

- Dosing pump with stroke length or frequency control

- Chemical tank with mixer, suction strainer, NRV, pulsation dampener, and calibration column

- Injection quill at the pipeline or tank

Benefits and Advantages

- Process performance: Tight pH bands improve reaction yields, coagulation, CIP effectiveness, and product quality.

- Operational efficiency: Auto start-stop, alarm handling, and proportional control keep operators focused on exceptions.

- Compliance and data: Event logs, trends, and audit trails simplify environmental reporting.

- Asset protection: Stable pH reduces corrosion and scaling in downstream equipment.

- Sustainability: Right-sized dosing cuts chemical consumption and neutralization by-products.

How to Choose the Right pH Dosing Pump

Key Selection Factors

- Capacity and pressure: Define max and normal flow, discharge pressure, and turndown ratio required.

- Chemical compatibility: Select materials for acids, caustic, coagulants, or neutralizers (e.g., PTFE diaphragms, SS316, PVDF, EPDM, FKM).

- Control strategy: Manual, on-off, proportional, or full pH controller with PID.

- Accuracy and turndown: Aim for linear turndown 10:1 to 100:1 depending on dynamics.

- Environment: Enclosures for outdoor, wash-down, or hazardous areas.

- Maintenance access: Valve kits, tubing, and diaphragms should be simple to swap.

Small-Scale vs Large-Scale

- Small plants & OEM skids: Solenoid or peristaltic pumps with compact controllers, limited I/O, and panel-mount displays.

- Large treatment systems & process plants: Hydraulic diaphragm metering pumps with pulse dampeners, VFD dosing, redundant pumps, and DCS integration via 4–20 mA or Modbus.

Quick Decision Checklist

- Do we know peak flow and worst-case pH deviation?

- Is the chemical aggressive or viscous?

- Do we need PID control and data logging?

- What accuracy and turndown are required?

- Any ATEX or hazardous-area requirement?

- What is the planned maintenance window and spares policy?

Considerations: Efficiency, Cost, Sustainability

- ROI and lifecycle cost: Consider pump efficiency, diaphragm life, check-valve reliability, and chemical savings from better control.

- Energy efficiency: Solenoid units suit low flow; for higher capacities, efficient hydraulics or VFDs reduce energy.

- Sustainability: Accurate metering lowers neutralization sludge and reduces chemical transport.

- Safety: Secondary containment for chemical tanks, leak-detection switches, foot valves with strainers, and back-pressure valves for stable metering.

Common pH Dosing Options

| Pump Type | Typical Flow Range | Pressure Range | Best For | Notes |

|---|---|---|---|---|

| Solenoid metering | Low | Low–Medium | Compact panels, OEM | Economical, simple set-up |

| Mechanical diaphragm | Low–Medium | Medium | Utilities, general pH correction | Robust, wide material options |

| Hydraulic diaphragm | Low–High | Medium–High | Chemical processing, critical duty | Leak-free, high reliability |

| Peristaltic | Low | Low | Viscous or shear-sensitive | Easy tube replacement |

Application Snapshots

- WTP/ETP/STP: Lime or caustic dosing for acidic influent; acid dosing for alkaline effluent.

- Food & beverage: CIP solution neutralization and product pH correction.

- Pharma & biotech: Buffer preparation and waste neutralization with traceability.

- Chemicals & coatings: Reaction pH control for consistent polymerization and color.

Controls and Automation: Making It Automatic

A pH controller compares live pH to the setpoint and changes pump strokes or speed. This is similar to temperature PID control, but with chemical dosing as the actuator. Modern systems integrate with SCADA or PLC for alarms, dosing totals, and interlocks like low-level tank trips or high-pH bypass logic.

Installation Best Practices

- Place the pH probe in a well-mixed location with proper flow across the sensor.

- Use an injection quill downstream of mixing points to avoid chemical short-circuiting.

- Add pulsation dampeners and back-pressure valves for steady flow.

- Calibrate with a calibration column and keep spare wet-end kits.

- Implement proper sensor calibration and buffer solutions at defined intervals.

Mini Case Examples

- ETP neutralization: Switching from manual acid buckets to an automatic pH dosing system cut chemical use by 18% and eliminated off-spec discharges.

- Beverage line: Replacing a worn peristaltic with a diaphragm metering pump stabilized pH within ±0.1, improving taste consistency and reducing rework.

FAQs

-

What makes a pH dosing pump different from a standard chemical pump?

It is designed for precise, repeatable metering at low flows, often with stroke or speed control and anti-siphon, back-pressure, and calibration components.

-

How does a pH controller relate to a dosing pump?

The controller reads pH and modulates the pump output to maintain the setpoint. Dosing is proportional to the error and process dynamics rather than constant. - Why do experts prefer automatic pH dosing over manual addition?

Automation reduces operator variability, chemical waste, and compliance risk while improving product quality.

-

Can a single system handle both acid and alkali dosing?

Yes, with dual pumps and appropriate interlocks. Many plants run two chemical tanks and select the dosing stream based on pH deviation.

-

How often should I calibrate the pH probe?

Weekly to monthly depending on duty. Always use fresh buffer solutions and replace aging probes proactively.

-

What materials should I choose for corrosive chemicals?

Use PTFE diaphragms, PVDF or SS316 wetted parts, and compatible elastomers like EPDM or FKM. Check supplier chemical-compatibility charts.

-

Is a peristaltic pump suitable for pH correction?

For low flows and certain chemicals, yes. For higher pressures or tighter accuracy, diaphragm metering pumps are often better.

- Do digital pH dosing systems support SCADA?

- Modern controllers provide 4–20 mA, pulse, or Modbus outputs for PLC and SCADA integration along with alarm relays.

- What safety features should I add?

- Secondary containment, low-level float switches, pressure relief, non-return valves, and eyewash stations near chemical tanks.

- Quick Buyer’s Checklist

- Defined pH range and flow variability

- Required accuracy and turndown

- Chemical and materials compatibility

- Safety, containment, and interlocks

- Controller I/O for PLC or SCADA

- Spares, service, and documentation

If you want stable, compliant, and low-waste pH control, a well-sized pH dosing pump paired with the right pH controller is the simplest path. Depending on your flow, chemistry, and integration needs, choose from solenoid, diaphragm, hydraulic, or peristaltic architectures to keep your line in spec every hour of the day. Evaluate your conditions, pick the control strategy, and standardize on a serviceable design to lower lifecycle cost.

Need help? The Verito Engineering team can guide you with all the relevant details for pH dosing pumps and systems. Connect with us to know more.