Injection quills and sample quills serve distinct purposes in industrial fluid handling systems. This article explains the functional and design differences between the two, outlines their specific roles in oil & gas, water treatment, and process manufacturing, and helps buyers choose the right solution based on operational intent.

Understand the Function of Injection Quills in Process Systems

Injection quills deliver precise volumes of chemicals into a process stream, ensuring proper dispersion and reaction efficiency. They are commonly used for injecting acids, coagulants, biocides, inhibitors, or pH control agents into pipelines, tanks, or reactors. The quill ensures the chemical reaches the centerline or optimal mixing zone, preventing damage to pipe walls or incomplete reactions.

Understand the Function of Sample Quills in Industrial Monitoring

Sample quills extract small, representative fluid samples from pipelines without disturbing flow conditions or introducing contamination. These quills enable real-time monitoring of process fluids, such as analyzing chemical concentration, quality, or contamination levels. They are critical in quality assurance, compliance, and closed-loop control in process plants.

Compare the Design of Injection Quills and Sample Quills

Injection quills and sample quills differ significantly in their tip geometry, flow path, and integration method.

- Injection quills: Feature an orifice or slotted tip designed to direct flow downstream. May include check valves, isolation valves, and retractable stems for live-line access.

- Sample quills: Feature a chamfered or small-bore port to minimize disruption while drawing samples. Usually include a sample tube, non-return mechanism, and connection to sampling bottles or analyzers.

- Materials: Both may be constructed from SS316, Hastelloy, or PTFE, depending on fluid properties, but sample quills often require stricter cleanliness standards.

Use Injection Quills for Controlled Chemical Delivery

Injection quills are best suited for injecting treatment chemicals where accurate placement and prevention of backflow are required. These quills typically work with dosing pumps and are calibrated for variable dosing volumes. Applications include:

- Oil and gas: Injecting methanol, corrosion inhibitors, and scale reducers into wellhead or pipeline systems.

- Water treatment: Dosing chlorine, alum, or lime into pipelines and tanks to maintain water quality and prevent biological growth.

- Chemical processing: Introducing catalysts, neutralizers, or additives into reaction vessels under pressure and temperature.

Use Sample Quills for Representative Fluid Monitoring

Sample quills are designed to collect a representative sample of process fluids without introducing flow turbulence or sample dilution. They enable lab or inline analysis of chemical properties such as pH, ORP, turbidity, and composition. Applications include:

- Refining and petrochemicals: Sampling hydrocarbons, condensates, or mixed process fluids for lab testing.

- Power plants: Monitoring boiler feedwater, cooling water, and condensate chemistry.

- Pharmaceuticals and food: Collecting sterile samples for microbiological or batch release testing.

Compare Safety and Installation Requirements

Each quill type has unique safety, sealing, and installation requirements due to the direction and purpose of flow.

- Injection quills: Often installed with isolation valves, retraction assemblies, and check valves to prevent backflow and allow safe maintenance under pressure.

- Sample quills: Require leak-free sampling connections and often include purge systems or inert gas isolation to avoid cross-contamination.

- Mounting: Both use threaded, flanged, or compression fittings, but sample quills may require stricter alignment to flow profile for accuracy.

Select the Right Quill Based on Process Objectives

The choice between injection and sample quills depends on whether the goal is to add chemicals or extract fluids. Use this checklist to guide selection:

- Choose injection quills: If the application requires accurate chemical addition, anti-siphon protection, or rapid mixing in a high-velocity stream.

- Choose sample quills: If the objective is to analyze fluid properties for quality control, automation feedback, or environmental compliance.

- In dual-use systems: Consider using both types at separate locations to maintain dosing accuracy and process visibility.

Conclusion

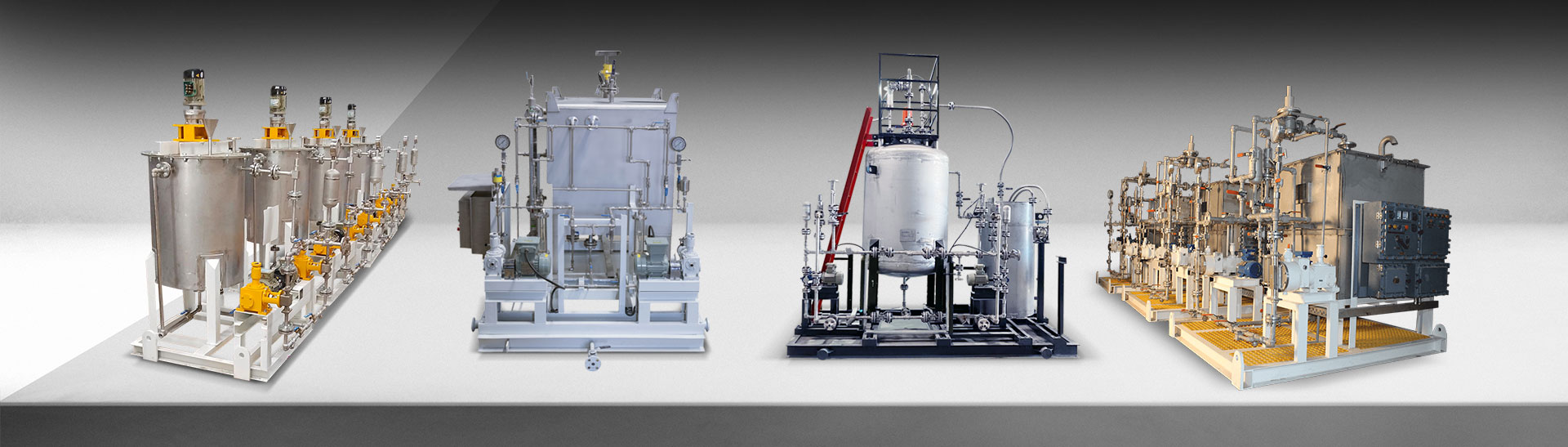

Injection quills and sample quills serve different but equally important roles in industrial dosing and monitoring systems. While injection quills introduce chemicals precisely into pipelines or tanks, sample quills withdraw fluid for process validation and quality control. Verito Engineering Pvt. Ltd. manufactures both types, engineered for durability, chemical resistance, and integration into high-performance dosing systems across water, oil & gas, and manufacturing sectors.